service@fannal.com +86-571-85161516

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-03 Origin: Site

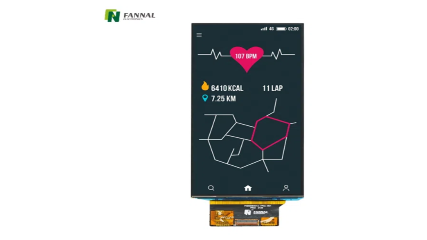

In today’s digital age, displays are central to our daily lives. Whether it’s smartphones, smartwatches, televisions, or laptops, the display is often the first thing consumers notice and the component they interact with the most. Among the many display technologies, the AMOLED display (Active Matrix Organic Light Emitting Diode) has become increasingly popular due to its vibrant colors, deep blacks, and energy efficiency.

However, not all AMOLED panels are equal in quality. For both consumers buying devices and professionals working with display manufacturing, knowing how to check an AMOLED display is essential. This article will guide you through the characteristics of AMOLED displays, the tests used to evaluate them, and what to look for to ensure you are getting the best quality.

AMOLED stands for Active Matrix Organic Light Emitting Diode. Unlike traditional LCDs, which rely on backlighting, AMOLED displays use organic compounds that emit light when an electric current passes through them. Each pixel generates its own light, which allows for:

True blacks: When pixels are turned off, they produce complete darkness.

High contrast ratios: Vibrant and striking visuals compared to LCDs.

Energy efficiency: Darker screen usage consumes less power.

Thin and flexible design: Allows for curved or foldable displays.

These qualities have made AMOLED displays the go-to technology for premium smartphones and cutting-edge consumer electronics.

Not all AMOLED panels are of the same quality, even when advertised under the same name. Issues such as uneven brightness, dead pixels, or screen burn-in can affect user experience. For manufacturers, thorough testing ensures product reliability and customer satisfaction. For consumers, it helps make informed purchasing decisions and spot defects early.

Key reasons to check an AMOLED display include:

Ensuring visual performance – vibrant colors, deep blacks, and uniform brightness.

Detecting manufacturing defects – such as dead pixels or uneven color distribution.

Evaluating durability – checking for potential long-term issues like burn-in.

Verifying authenticity – confirming that the display is genuine and not a low-quality replacement.

Ensuring the quality of an AMOLED display requires careful inspection and testing. Whether you are a consumer evaluating a new device or a technician assessing panels in production, there are several methods available, ranging from simple visual checks to advanced diagnostic tools. Here’s a comprehensive breakdown:

A basic but effective way to evaluate an AMOLED display is through visual examination. Start with brightness uniformity by displaying a pure white screen. Check carefully for any spots, uneven lighting, or patchy areas, which may indicate defects or inconsistencies in the panel. Next, assess color accuracy by showing solid colors like red, green, and blue. The saturation and hue should remain consistent across the entire display, without noticeable shifts. Dead or stuck pixels are another common issue; display a completely black screen and look for tiny points of light that shouldn’t be present. Finally, examine sharpness and resolution by zooming in on detailed text or images to ensure there is no pixelation, blurring, or edge distortion.

For smartphones and tablets, specialized applications like Display Tester or Dead Pixel Detect allow users to conduct more thorough tests. These apps can generate preset patterns, color gradients, and solid-color screens to identify irregularities in brightness, color, or pixel function. These tools are especially helpful for consumers who want a quick yet effective evaluation without professional equipment.

One of the most celebrated features of AMOLED technology is its ability to produce true blacks. Displaying an all-black image in a dimly lit room provides a simple test: a high-quality AMOLED panel will appear completely dark, seamlessly blending with the device bezel. Any grayish or uneven glow could suggest a substandard display or potential issues with pixel performance.

AMOLED displays are known for maintaining color fidelity and brightness at wide angles. Tilt the device to the side, up, and down to observe if colors remain consistent and brightness does not noticeably dim. Significant color shifting or reduced luminance may indicate inferior panel quality.

Burn-in occurs when static elements, like navigation bars or app icons, leave faint permanent marks on the screen over time. To test for this, display solid colors and examine whether residual ghost images are visible. Early detection helps prevent long-term usability issues.

For manufacturers, repair centers, or labs, professional diagnostic equipment provides the most precise evaluation. Colorimeters, spectroradiometers, and luminance meters measure brightness, color accuracy, gamma curves, and uniformity with scientific precision. These tools are essential for quality control in production environments and for certifying display performance.

By combining these approaches—from simple visual checks to advanced instrumentation—users and professionals can accurately assess AMOLED display quality and ensure optimal performance, durability, and visual experience.

When checking an AMOLED display, you might encounter the following issues:

Dead or stuck pixels: Small dots that remain lit or unlit.

Color banding: Visible steps in gradients, indicating poor calibration.

Uneven brightness: Certain areas of the screen appear brighter or dimmer.

Burn-in: Permanent ghost images from static UI elements.

Excessive blue light: Poor calibration can strain eyes over time.

Identifying these problems early allows consumers to request replacements or manufacturers to improve quality control.

If you’re purchasing a device with an AMOLED display, here are practical steps to ensure quality:

Run basic tests at the store using test apps or by displaying solid color images.

Check black screen performance in a dim environment.

Compare viewing angles with other devices side by side.

Look closely for dead pixels or ghosting.

Adjust brightness levels to see if the display remains uniform.

These simple checks can help avoid long-term dissatisfaction.

On the production side, manufacturers implement strict quality control processes:

Automated Optical Inspection (AOI): Cameras and software analyze displays for uniformity and defects.

Environmental Testing: Displays are exposed to heat, humidity, and pressure to assess durability.

Burn-in Resistance Testing: Long-duration static images are displayed to evaluate resistance.

Calibration: Color and brightness are fine-tuned to meet industry standards.

These processes ensure AMOLED panels meet consumer expectations and extend their operational lifespan.

As AMOLED displays continue to dominate the premium device market, testing methods are also evolving. Emerging trends include:

AI-driven defect detection: Using machine learning to spot minute inconsistencies.

Flexible and foldable display testing: Addressing durability in next-gen designs.

Blue-light reduction technologies: Measuring eye-comfort features.

Higher resolution standards: Testing for 4K and beyond in portable devices.

These innovations will further improve quality assurance, benefitting both manufacturers and consumers.

AMOLED displays have revolutionized the way we experience visuals on modern devices, offering unmatched contrast, rich colors, and energy efficiency. However, their advanced technology also requires careful evaluation to ensure performance and longevity. By following basic consumer tests or leveraging professional diagnostic tools, both individuals and manufacturers can guarantee high-quality AMOLED panels.

If your business is looking for advanced AMOLED display solutions, working with an experienced provider is key. Fannal Display specializes in high-quality display technologies and can help you find the right solutions for your products. Reaching out to their team may be the first step toward ensuring your devices deliver outstanding visual experiences.

Q1: What are the most effective ways to check an AMOLED display for defects?

A: The most effective checks include visual inspection for dead pixels, uniformity and color shift tests, brightness consistency checks, and using diagnostic apps to detect burn‑in or subpixel issues.

Q2: How can I tell if the AMOLED display has burn‑in or image retention?

A: Display a solid color (white, gray, black) and look for ghosting of previous images. Persistent residual images that don’t disappear after a few minutes typically indicate burn‑in.

Q3: Is it necessary to use testing software for AMOLED quality checks?

A: Testing software tools can help identify pixel defects and color accuracy issues that are hard to see with the naked eye. They’re recommended for thorough quality assessment, especially in production or QC environments.

Q4: What common issues should I look for when inspecting an AMOLED screen visually?

A: Check for dead or stuck pixels, uneven brightness, noticeable color shifts at different angles, and any irregular black levels in dark areas.

Q5: Can environmental factors affect AMOLED display performance during testing?

A: Yes. Ambient lighting, viewing angle, and screen reflections can influence perception. Conduct tests in controlled lighting and view the screen from multiple angles to ensure accurate assessment.